Loading Technology

Accesories

Sectional door

Mechanical eco leveller

The PECO2 mechanical eco leveller (PROMStahl ECONOMICAL) belongs to PROMStahl’s wide product range and is especially suited for loading and unloading vehicles with beds the height of which only slightly differs from that of the dock. The PECO2 leveler is therefore the perfect solution for fleets with vehicles of nearly identical lorry bed heights.

Details

Fast installation and the possibility to integrate it into already existing loading situations are among the big advantages of this leveller. The PECO2 leveller is mechanically operated by means of a gas spring so that it can be handled by just one person without any problems: the platform is lifted with the swing lip automatically swinging out in its uppermost position and coming to rest on the lorry bed. During the loading and unloading process the PECO2 leveller is in its automatic floating position, i.e. it follows the height fluctuations of the vehicle.

When the leveller is its resting position, the platform is in a slightly slanted position.

The PECO2 leveller meets the requirements of the latest European standard (DIN EN 1398).

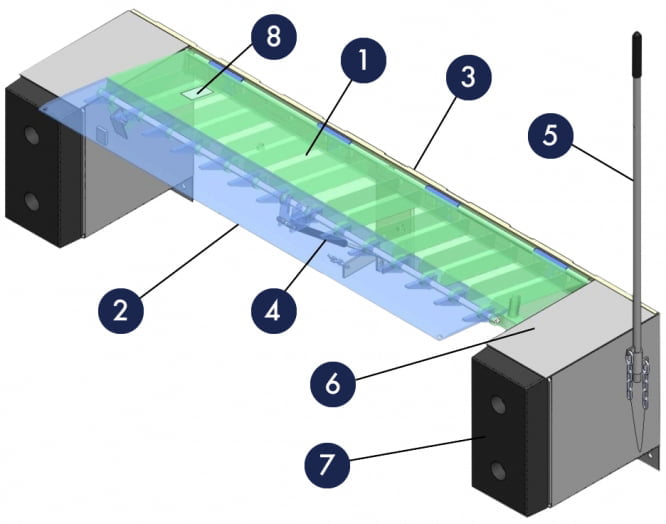

1. Platform

2. Swing lip

3. Rear frame

4. Gas spring

5. Operating rod

6. Buffer support

7. Rubber puffer

8. Identification plate

Mechanical eco leveller PECO2 Type R

| Type R | |||

|---|---|---|---|

| Overall length of the leveller with the hinge lip swung out (OL) | 760 | ||

| Lip length | 360 | ||

| L1 (length of the buffer structure + buffer thickness) | 545 (PBGP 500 x 250 x 90) 545 (PEHD 500 x 250 x 50) | ||

| Contact depth in the truck (Distance between the buffer and the swung out hinge lip) | 215 (PBGP 500 x 250 x 90) 215 (PEHD 500 x 250 x 50) | ||

| Nominal width (NW) | 1.750 | 2.000 | 2.250 |

| Modular width (MW) | 2.300 | 2.250 | 2.800 |

| Load capacity [kN] | 60 | ||

All dimensions in mm.